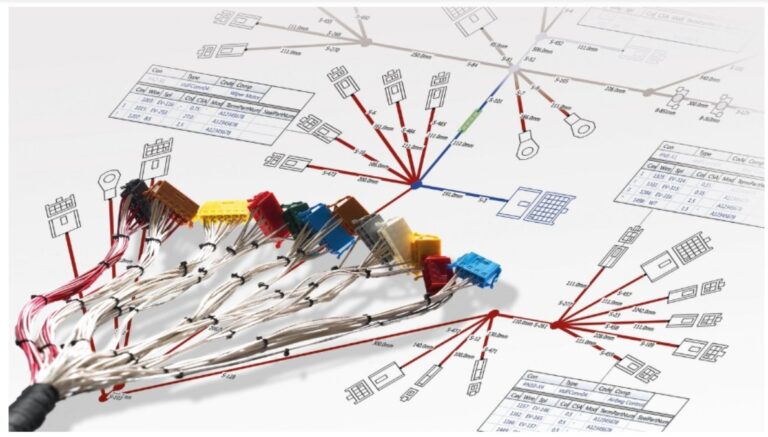

The design phase is the critical first step in the wire harness manufacturing process, as it is in any electronics production. Wire harnesses are used in a wide variety of applications, from industrial machinery panels and washing machines to beneath the glove box in automobiles. Their main function is to efficiently transmit power and data. Each application demands a unique design tailored to its specific requirements, making this phase one of the most challenging aspects of wire harness production.

During the design process, engineers must address several key factors:A well-designed wire harness not only supports the system’s functionality but also ensures durability and efficiency throughout its lifecycle.

The prototyping phase allows engineers and product designers to create a real-world model of the wire harness before full-scale production. This step is crucial for testing the harness’s functionality and performance in the actual application. By evaluating the prototype in its intended environment, designers can identify and address any issues, ensuring the wire harness meets performance standards before beginning mass production.

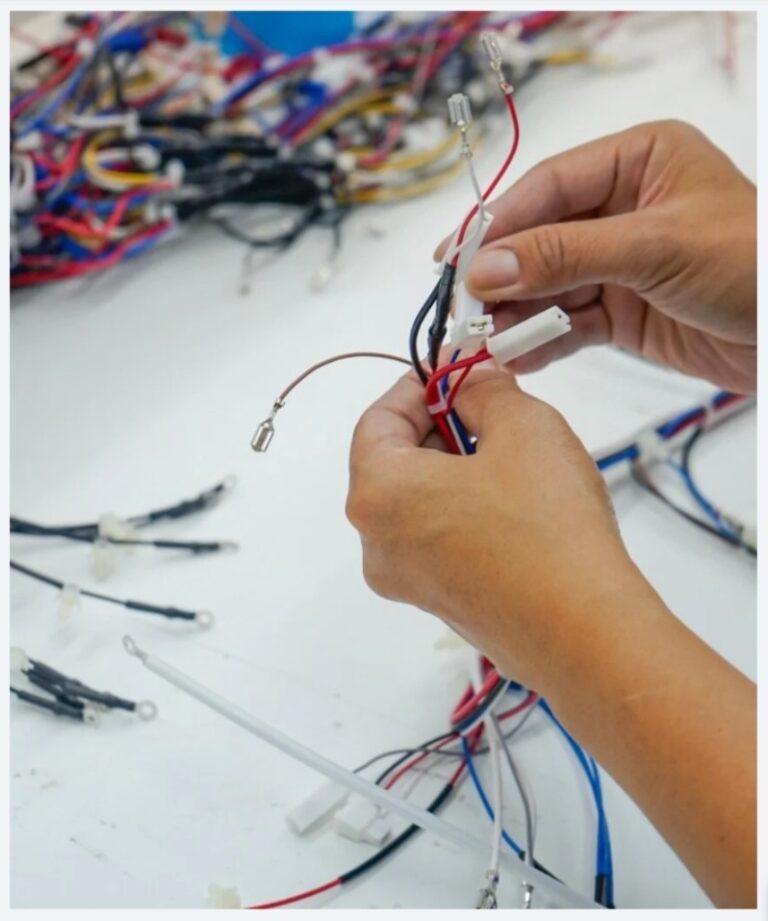

Maintaining high-quality standards and minimizing errors is crucial during the production and assembly of wire harnesses. Every harness must adhere to strict design specifications to ensure optimal performance. Despite the rise of automation across industries, wire harness production still relies heavily on manual assembly due to the complexity and intricacy of the process.

While some automation can be incorporated, the handcrafting of wire harnesses remains necessary to handle the numerous detailed and time-consuming steps involved. Though it can be a challenging and labor-intensive process, manual assembly continues to be the most cost-effective method for producing high-quality wire harnesses.

The first step in creating a wire harness is wire cutting. In this phase, the wires are precisely cut to the required lengths using specialized wire-cutting machines. Accuracy in this step is essential, as it sets the foundation for the rest of the assembly process.

The next step is stripping, where the insulation at the wire ends is carefully removed to expose the cores. This is necessary to make secure connections with terminals, connector housings, or modules in the later stages of assembly.

In the assembly phase, the wires are carefully organized and assembled into a harness to meet the design specifications. This is done using a workbench or assembly board to ensure accuracy. Wires are routed through protective sleeves, and fabric tape is applied where needed, such as on branch-outs from wire strands.

Manual assembly is essential for tasks like crimping terminals onto wires, especially when multiple wires need to be connected to a single terminal. Additionally, sleeve insertions, strand fastenings, and securing the harness with tape, clamps, or cable ties are all done by hand to maintain precision and quality.

Safety is paramount in any electronic device, and wire harnesses are no exception. Testing is an integral part of the manufacturing process to ensure the final product is safe, durable, and functional in real-world conditions. Rigorous testing helps verify that the wire harness can withstand the demands of its specific application.

Looking for high-quality wire at the best price? Get a personalized quote in just a few clicks!